Our pail filling systems are suitable for (semi-) automatic filling of liquid and pasty products, such as sauces, yoghurt, cheese, butter ,margarine, fats and paint. The modular systems are characterized by the hygienic design, optimal accessibility for cleaning, and more.

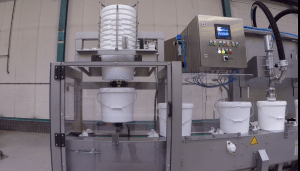

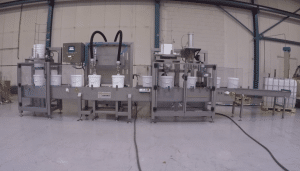

The filling system is suitable for filling of various types, materials and sizes of pails. The system can be delivered with different variations, such as single head or multi-head line fillers.

By changing the format parts, the user has control over a flexible machine that can be quickly converted.

Our systems are build up using customer specific standard modules, so that the needs of the customer can be met. A filling line can exist of the following modules:

✓ Input buffer line

✓ De-stacker

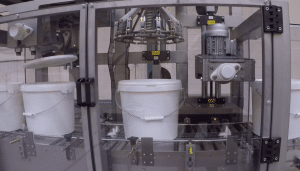

✓ Index transport

✓ Filling station

✓ Seal unit

✓ Lid delivery and closing station

The denesting of pails is done completely automatic and controlled. For transporting and positioning the pails, a servo control is used so that precise movement and positioning is guaranteed.

The filling can done done based on weight, volume or a combination of both. A continuous feedback to the filling unit is always present, resulting in maximum filling accuracy.

Depending on the product, the filling system can be delivered with one or multiple filling heads, which can be exchanged easily.

The filling system can be equipped with a top sealer for the application of foil, whereby it is possible to choose for fumigation with, for example, nitrogen.

The lid is applied by using a lid mounting manipulator in combination with a pressing unit.